How to Create a Tech Pack for Clothing: Complete Guide

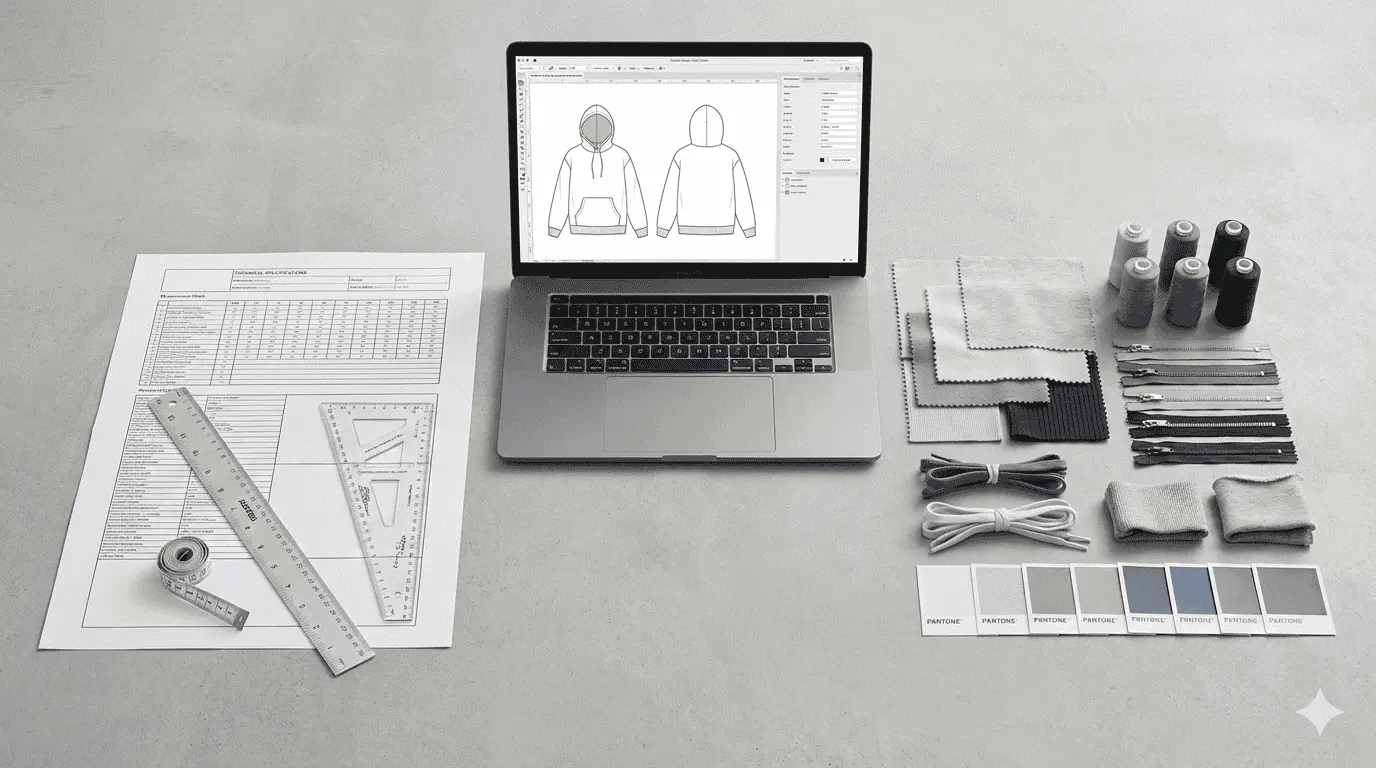

The gap between the design concept and a production-ready garment consists of a single document: a tech pack. It is a universal language between designers, brands, and manufacturers that removes doubts and ambiguity, and makes sure that your creative vision is accurately translated into final products. In addition to controlling quality and minimizing the number of rework and expensive changes, creating tech packs to establish effective communication with your custom clothing manufacturer, whether you are a startup founder working on your first line or an established brand streamlining production processes, it is imperative to perfect the process of creating tech packs.

An effective tech pack is both a guide and a contract that will explain all the specifications of fabric composition and colourways, stitching methods, as well as labeling standards. It secures your intellectual property, reduces cross-functional miscommunication over time zones and language barriers, and gives you a point of reference on quality assurance throughout the production process.

Ready to convert your design into production-ready specifications? Contact Innovate Apparel and discover how our team can help you in the process of developing tech packs and provide you with a perfect execution of your outfits.

What are Tech Packs in the Clothing Industry?

A technical package, also known as a tech pack, is an elaborate document that includes all details that a custom clothing maker requires to create your garment, just as it was imagined. Consider it as a fashion blueprint architecture. Just as a contractor would not know how to build a house without a technical design, a manufacturer would not know how to make clothes without the technical requirements. This document lies in the middle of the creative design and the production industry, where the aesthetic vision is converted into measurable and replicable instructions.

The development of tech packs is related to the globalization of the fashion industry and technological improvement. In the past, designers could have engaged the local seamstresses to do the work and worked with them by providing face-to-face fittings and verbal instructions on the changes to make. The modern global supply chains require standardized documentation that moves across continents without any hassles so that the quality of production remains the same, no matter the place of manufacture.

Why tech packs matter for your brand:

- Eliminate costly miscommunication – Clear specifications prevent expensive sample revisions

- Protect intellectual property – Document proprietary design elements and construction techniques

- Enable quality control – Create measurable standards for production verification

- Streamline manufacturer relationships – Professional documentation builds credibility with production partners

- Support scaling efforts – Replicable specifications allow consistent production across multiple runs

Beyond their practical production function, tech packs serve multiple strategic purposes. They establish a permanent documentation of design specifications which can be consulted when a repeat production run is being done, variations by the season, or when a different manufacturer is being used. Here, at Innovate Apparel, we have witnessed the benefits of having detailed tech packs with any brand when it comes to turnaround time, reduced manufacturing mistakes, and better relationships with manufacturers than when it comes to using incomplete specifications.

Essential Components of a Professional Tech Pack

Technical Sketches and Design Specifications

Any tech pack has a visual base, starting with accurate technical drawings, also known as flats or technical drawings. Technical flats, whereas fashion illustrations focus on the mood and pretty look and feel of the garment, show it dead flat on a table, front and back with both views being precise in proportions and construction. These drawings do not involve artistic interpretation, and they portray the way the seams are to fall, the location where pockets are to be, and the way design features should be.

The professional technical flats are more often prepared with a special program, such as Adobe illustrator that enables a clean line, accuracy in measurements, and simple adjustments. Along with your technical flats, there should be callouts that show special construction features and that have to be given special consideration.

Key elements your technical sketches must include:

- Front and back view drawings with proportionally accurate representations

- Detail callouts indicating topstitching, reinforcements, and special features

- Construction annotations specifying seam placements and assembly techniques

- Hardware specifications showing zipper, button, and closure placements

- Pantone color references for accurate color reproduction across production

Technical sketches are even more important in the case of brands that create specialized products, such as custom hoodies or custom jackets, because these pieces are rather complex. A tech pack for a hoodie should define the size of the hood, the size of the drawstring, the construction of the kangaroo pockets, the details of the cuff and hem ribbing, and the attachment points for the lining.

Measurements and Grading Specifications

The measurement section represents the numerical heart of your tech pack, translating design vision into precise dimensions that determine fit, proportion, and wearability. A detailed measurement chart includes all significant dimensions of your garment across all size lines that your brand will sell. The measurements are supposed to be recorded in a tabular format such that the different sizes are placed in separate columns, and different measurement points are placed on separate rows.

Grading specifications describe how measurements vary within your scale of size, so that in increasing or decreasing size, they change in proportion, and the garment has the fit and silhouette you intend. A size medium may be 22 inches in width of a chest, but how far should that size be extended to make large, extra-large, and so on?

Critical measurements to include in your tech pack:

- Overall garment length (measured from high point shoulder to hem)

- Chest width (measured one inch below armhole, laid flat)

- Shoulder width (seam to seam across back)

- Sleeve length (from shoulder seam to cuff edge)

- Armhole depth and circumference

- Neck opening dimensions

- Hem width and any style-specific measurements

Your measurement instructions must also specify the point of measurement on the garment, as well as whether it is laid flat or circumference. The tolerance ranges include consideration of manufacturing processes being inherently variable – specifying acceptable variation (usually +/- 0.25 to 0.5 inches) will allow manufacturers to know what you expect of them as far as quality is concerned, but not necessarily unrealistic accuracy.

Materials, Trims, and Construction Details

Material specifications constitute the actual material of your garment, and they define each aspect of it, such as drape, texture, care, etc. Main fabrics in your tech pack should be identified by fiber content, weight, method of construction, and finish. Instead of just stating cotton jersey, state 100 percent combed ring-spun cotton single jersey, 180 GSM, pre-shrunk, and enzyme washed.

The specifications of trim should also receive as much attention as possible, as these items have a substantial influence on the aesthetics and functionality. Types and colors of thread to be used in different applications, construction seams may need polyester thread to provide strength, but topstitching may need contrasting cotton thread to provide a visual effect.

Complete bill of materials should specify:

- Main fabric – Fiber content, weight, construction, finish, color references

- Lining materials – Type, weight, attachment methods if applicable

- Thread specifications – Types for construction seams vs. topstitching

- Closure components – Zippers (type, length, material), buttons (diameter, style, material)

- Labels and tags – Care labels, brand labels, hangtags with placement instructions

- Packaging elements – Poly bags, tissue paper, custom boxes or mailers

Construction notes are used in the assembly process and are used to identify the type of seams, the number of stitches, and the finishing methods. A flat-felled seam provides different aesthetics and durability than a simple overlock seam. Your tech pack should specify which construction method applies to each seam in your garment. In complicated categories such as custom bulk apparel, the use of uniform construction specifications across a variety of styles will provide a unifying quality standard through your line.

Step-by-Step Process for Creating Your Tech Pack

Research and Preparation Phase

Before you write your first tech pack, take time to conduct research and preparation to lay the groundwork for your successful production. Begin by comparing similar outfits in your target market, buying competitor items or reference items, which represent good standards or construction methods, or fit qualities that you wish to copy or better. Dismantle these pieces very thoroughly, and record the types of seams, type of stitch, fabric weight, and the order of construction.

Gain a clear conception of the size expectations and fit preferences of your target customer, which directly affects your measurement and grading decisions. Various markets have varied fit expectations – European sizing is generally smaller than American sizing, athletic body shapes demand different ratios than standard sizing, and the modern fashion is more tolerant of oversizing, whereas the conventional categories have closer fits.

Essential preparation steps before creating your tech pack:

- Collect reference samples representing your target quality level

- Deconstruct similar garments to understand construction methods

- Conduct fit sessions with models representing your target demographic

- Source fabric swatches and trim samples for your specifications

- Research your custom clothing manufacturer’s capabilities and requirements

- Create standardized templates for consistency across your collection

Have everything you need when you start your tech pack documentation, such as design drawings, fabric samples, trim samples, and brand specifications. Create connections with your custom clothing producer at an early stage, as you can have more experienced manufacturers of production who may also offer some advice on technical specifications and other feasible ways of construction.

Drafting Technical Specifications

When assembling your tech pack, the most important step is to develop proper technical flats, which will be the reference point of all the other specifications. Draw clean, scalable illustrations with a vector-based application such as Adobe Illustrator or fashion design-specific applications such as CLO 3D or Browzwear. Most basic garment shapes should be used initially, then you can add some construction details such as seam lines, topstitching, closures, and design features.

Get your measurement chart by setting up a base size (whatever size fits well with most brands) with perfect ratios that will give you your desired fit and silhouette. Use an existing well-fitting garment as a starting point, taking precise measurements and adjusting based on your design variations. Once your base size is established, calculate grading increments for smaller and larger sizes.

Document all the material and construction specifications with accuracy that can do away with ambiguity. Prepare a bill of materials (BOM) with all the parts needed in the assembly of a garment, the principal fabrics, lining, interfacing, threads, buttons, zippers, labels, and packaging parts. Indicate the quantities required on every garment, taking into account the factors of waste and proper costing.

Review, Refinement, and Manufacturer Collaboration

After you have drafted your first tech pack, make sure you have done extensive internal reviews before you send it to manufacturers. Look for inconsistencies among the technical sketches and specifications, make sure that measurements are reasonable and feasible, and verify that the materials and trims are all easily accessible or have approved substitutes.

Send your technology pack to your custom apparel producer to be reviewed and provide feedback on technical aspects. Skilled producers are able to foresee possible obstacles in the production process, propose changes to the construction that would enhance efficiency without damaging the design, as well as confirm that the given materials are suitable for your type of the garment.

Collaborative review process includes:

- Internal team review for consistency and completeness

- Manufacturer technical review for production feasibility

- Cost analysis and optimization discussions

- First sample evaluation against specifications

- Documented revisions addressing any discrepancies

- Final production-ready tech pack approval

Refine your tech pack based on manufacturer feedback and sample evaluations. Once your initial sample comes, make in-depth comparisons with your specifications, including measurements of all dimensions, scrutiny of the quality of construction, and evaluation of material performance. This continuous process of improvement will guarantee that the production units are of the standards you want and minimize the expensive mistakes that will arise once mass production has started.

Common Tech Pack Mistakes and How to Avoid Them

Lack of detail is the most common mistake in tech pack design, especially when the designer is a beginner and is unaware of the exact design detail needed to produce quality products. Even description such as normal hem or normal zipper gives the chance to the manufacturer to decide on the critical issues, but the interpretation of these words is not always exactly what the designer intended.

Inconsistent or missing measurements represent another common pitfall that leads to fit issues and sample revisions. Tech packs that include chest width but omit shoulder measurements, or specify lengths without indicating measurement starting points, create confusion during pattern development. Ensure your measurement chart is comprehensive, covering every critical dimension that impacts fit and appearance.

Top tech pack mistakes to avoid:

- Vague material descriptions – Always specify exact fiber content, weight, and finish

- Missing measurement points – Include comprehensive dimensions with points of measure

- Inconsistent terminology – Use standardized industry terms throughout

- Overlooking tolerance ranges – Specify acceptable measurement variations

- Ignoring production realities – Design with manufacturability in mind

- Inadequate visual references – Provide clear technical sketches and detail views

Failing to consider production realities often results in designs that are theoretically beautiful but practically problematic. Intricate construction details that require excessive labor, specified materials that aren’t readily available in needed quantities, or sizing ranges that require complex grading calculations can all inflate costs or delay production timelines. At Innovate Apparel, we work closely with brands during tech pack development, offering practical insights that optimize both quality and cost-efficiency.

Working with Your Custom Clothing Manufacturer

The relationship between brands and their custom clothing manufacturer should be collaborative rather than transactional, built on clear communication, mutual respect, and aligned quality expectations. When initiating partnerships with potential manufacturers, share your tech packs along with physical samples or detailed imagery that illustrate your quality standards.

Establish clear communication protocols that facilitate efficient problem-solving throughout the production process. Designate specific points of contact on both sides, define response time expectations for questions or approvals, and determine preferred communication channels, whether email, video calls, or project management platforms.

Build long-term relationships with manufacturers who consistently meet your quality and service expectations. Stable manufacturing partnerships provide numerous advantages: manufacturers become intimately familiar with your brand standards, reducing sampling iterations; you gain priority scheduling during peak seasons; and you develop trust that streamlines approval processes.

Expert Guidance for Successful Garment Production

Navigating the complexities of tech pack creation and garment manufacturing requires expertise that extends beyond design talent to encompass technical knowledge, production understanding, and industry experience. For brands new to custom manufacturing, partnering with experienced professionals can dramatically shorten learning curves, avoid costly mistakes, and accelerate time-to-market.

At Innovate Apparel, we recognize that tech pack creation represents a significant hurdle for many emerging brands. Our team includes technical designers with decades of combined industry experience who can review your tech packs, identify areas requiring additional detail, and suggest practical improvements based on production realities.

How expert guidance accelerates your success:

- Technical designers review and optimize your specifications

- Production experts identify potential issues before costly sampling

- Streamlined processes reduce development timelines

- Industry knowledge informs smarter material and construction choices

- Quality assurance systems ensure consistency across production runs

Beyond tech pack development, successful brands cultivate broader production literacy that informs smarter design decisions, more realistic costing, and better supplier relationships. Invest time in understanding garment construction fundamentals, fabric performance characteristics, and manufacturing processes. This ongoing education transforms you from a passive client into an informed partner who can collaborate effectively with manufacturers.

Ready to transform your designs into production-ready specifications with expert support? Contact Innovate Apparel today to discuss how our technical expertise and manufacturing capabilities can streamline your development process and ensure exceptional quality in every garment.